Team Members: Jessie Lyons- Chemical Engineering (4th year), Emily Mattson- Chemical Engineering (5th year), Libby Umlor- Chemical Engineering (3rd year), Kristen Kautz- Chemical Engineering (2nd year), Emmeline Beck- Electrical Engineering (3rd year)

The goal of this project is to design and operate a process to chemically recycle plastics into a viable source of fuel by breaking down the polymer chains into smaller hydrocarbons. With 27 million tons/yr of plastic being thrown out into landfills in the USA and only 3 million tons being recycled in 2018 alone, there is a demand for a better environmental and economical option than simply landfilling it. Creating a new product from a source of waste would help to produce value while simultaneously reducing the amount sent to landfills.

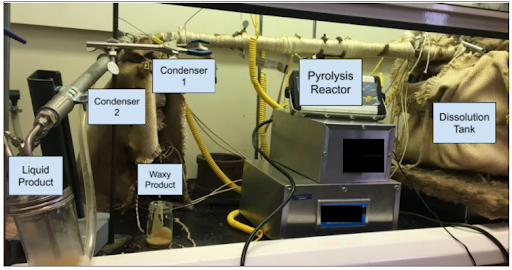

In the process, pyrolysis breaks down the plastic polymers which turns them from a mixture of waste plastics in solvent to smaller hydrocarbon chains. The products range from heavy fractions such as waxes, to liquid fractions and gases that are vented through a fume hood. These products are then analyzed using a batch distillation process in order to see the characteristics by using a distillation curve.